Alloy 926 is an austenitic, special stainless steel that was developed on the basis of the many times proven Alloy 904 L (1.4539). Due to its 6.5 % higher molybdenum concentration, Alloy 926 has a generally improved corrosion resistance and resistance against pitting corrosion and crevice corrosion compared to Alloy 904 L. This also has a positive effect on the resistance against stress corrosion that is induced by pitting corrosion.

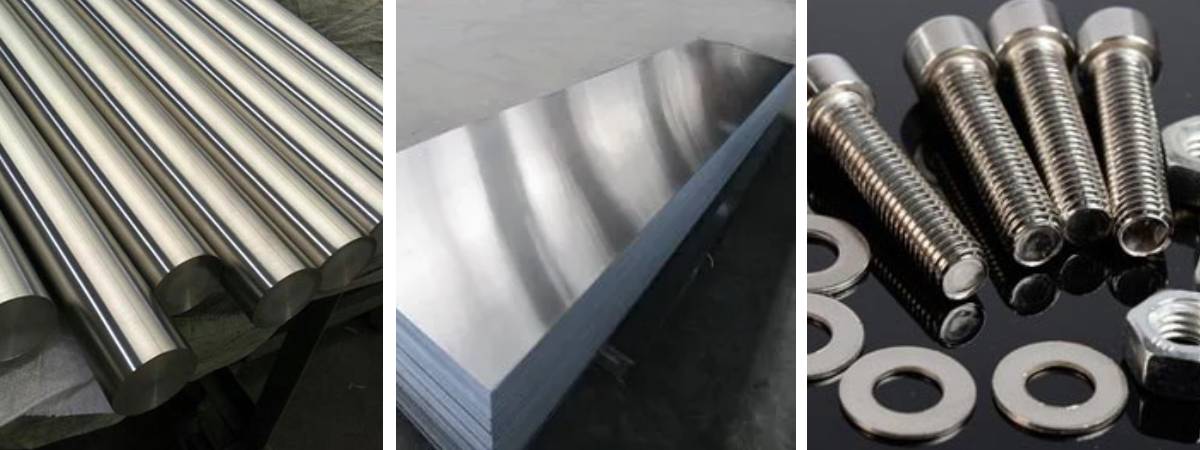

Alloy 926 Rods: Alloy 926 rods are a high-performance austenitic stainless steel product, designed to offer exceptional resistance to corrosion in aggressive environments. With a composition rich in nickel, chromium, molybdenum, and nitrogen, these rods provide superior protection against pitting, crevice corrosion, and chloride-induced stress corrosion cracking. This makes them ideal for use in demanding industries such as chemical processing, marine engineering, oil and gas, and pollution control. In addition to their outstanding corrosion resistance, Alloy 926 rods offer excellent weldability and strength, ensuring reliability in both high-temperature and high-pressure applications.

Alloy 926 Sheets: Alloy 926 sheets are highly durable and corrosion-resistant austenitic stainless steel products, engineered to perform in harsh and corrosive environments. Known for their exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in chloride-rich and acidic conditions, these sheets are widely used in industries like chemical processing, marine engineering, and oil and gas. The high nickel, chromium, molybdenum, and nitrogen content in Alloy 926 enhances its mechanical strength and resistance to localized corrosion, making it an excellent choice for applications requiring long-lasting performance, even in extreme environments.

Alloy 926 Fasteners: Alloy 926 fasteners are high-performance components designed to provide superior corrosion resistance and strength in demanding environments. Made from austenitic stainless steel, these fasteners offer excellent protection against pitting, crevice corrosion, and chloride-induced stress corrosion cracking, making them ideal for use in industries such as chemical processing, marine engineering, oil and gas, and pollution control. The high levels of nickel, chromium, molybdenum, and nitrogen in Alloy 926 contribute to its enhanced durability, ensuring that these fasteners maintain their integrity even in harsh, high-temperature, and high-pressure conditions.

- Very good resistance against chloride-induced stress corrosion.

- Increased resistance against stress corrosion in comparison to other austenitic stainless steels.

- Excellent general corrosion resistance when in contact with oxidizing and reducing media.

- Higher strength than Alloy 904 L (1.4539).

- low propensity to form inter-metallic phases.

- Approval for pressure vessels in the temperature range from -196 to 400 °C (-272.2 to 752 °F).

- Vaporizers, heat exchangers, tank housings, etc. in phosphorus acid production.

- Distributor systems and coolers for sulfuric acid plants.

- Concentration and crystallization plants in salt extraction by vaporization.

- Pump frames of oil extraction pumps

- Pump lines and couplings, wire lines in oil and gas extraction.

- Condenser pipes and pipework systems in power plants with heavily contaminated cooling water

- Parts for flue gas desulfurization that are exposed to modest corrosion strain

- Facilities and parts for the bleaching phase of the pulp industry

- Flexible pipes in the off-shore industry

- Tanks for storing and transport of aggressive chemical substances

| Size: | 0.1 mm to 120 mm thk x 1000 / 1220 / 1250 / 1500 / 2000×2000 / 2500 / 3000 / 5000 / 6000 |

| Form | Sheet, Plate, Coil, Flat, Strip, Circle, Profile, Shim, Foil, Chequered Plate |

| Range | C | S | N | Cr | Ni | Mn | Si | Mo | Cu | P |

| Min | - | - | 0.15 | 20.0 | 24.0 | - | - | 6.0 | 0.5 | - |

| Max | 0.02 | 0.010 | 0.25 | 21.0 | 26.0 | 1.0 | 0.5 | 7.0 | 1.5 | 0.03 |

| Density | Melting Range | Relative Magnetic Permeability at 20 ℃ (68 ℉) |

| 8.1 g/cm3 (506 lb/ft3) | 1,320 - 1,390 ℃(2,408 - 2,534 ℉) | 1.001 |

| Properties | 20 ℃/ 68 ℉ | 200 ℃/ 392 ℉ | 400 ℃/ 752 ℉ | 550 ℃/ 1022 ℉ |

| Yield Strength MPa/ksi |

300/43.5 | 190/27.6 | 160/23.2 | 105/15.2 |